Our threaded inserts for plastic are a versatile solution suitable for molded-in or pressed-in applications. The plastic threaded insert is either inserted into the product at the time of manufacturing as the plastic molds and hardens around it or pressed into a hole in the hardened, cool plastic, creating a secure and long-lasting fit. These plastic inserts are available in a range of sizes and designs to meet the needs of various applications and can improve the strength and durability of plastic products.

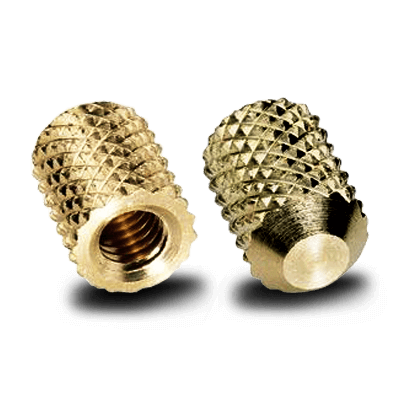

TYPE AA Molded-In Inserts feature a new design for molded-in use. Close tolerance of minor thread diameter and careful burnishing of inner thread crests assure snug fit on locating pins. Smooth ring on open end of insert eliminates knurl teeth showing on surface of molded part.

TYPE BB Molded-In Inserts feature a new design for molded-in use. Close tolerance of minor thread diameter and careful burnishing of inner thread crests assure snug fit on locating pins. Both ends of insert are chamfered to eliminate knurl teeth showing on surface of molded part.

Designed for fast easy press-in installation, providing permanent threads in aluminum, soft metals and plastics. The knurled body locks tightly in the host material and its thick wall design prevents thread distortion. It also can be swaged to metal tubing. Available in Plated Steel.

Versatile, economical and trouble free, they offer easy, high-speed installation. Curved hooks and lateral flutes lock them into plastics, particle board and wood. Install with ultrasonic or thermal tools or just hammer or press them in. Available in Brass.

A wide range of threaded inserts featuring patented designs for molded-in use. Close tolerance of minor thread diameter and careful burnishing of inner thread crests assure snug fit on pins. Extremely flat ends on inserts (with no burrs, ridges or other defects) mean no leakage of material on the face of the mold. Available in Brass, Aluminum and Stainless Steel.

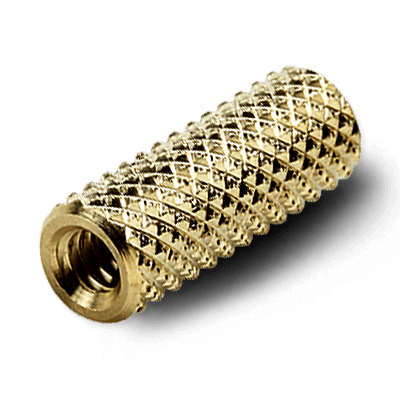

Spiral knurled, open or closed-ended inserts for pressing into soft materials such as plastics, foamed plastics and rubber. Ideal for use where minimal pull-out strength is needed, but some torque resistance is required. Can also be molded-in and feature patented I.D. design for use with locating pins. Available in Brass and Aluminum.

Threaded stud inserts featuring patented designs for molded-in use. Proportioned for maximum holding strength. Can be screwed to butt flush with a Yardley Type C Insert. Available in Brass.

For strong threads in plastics, soft metals and wood. Self-tapping, they provide high torque and pull-out resistance. Install with Yardley pneumatic inserter or insert driver. Available in Brass, Plated Steel and Stainless Steel (Coarse Series in Brass Only).